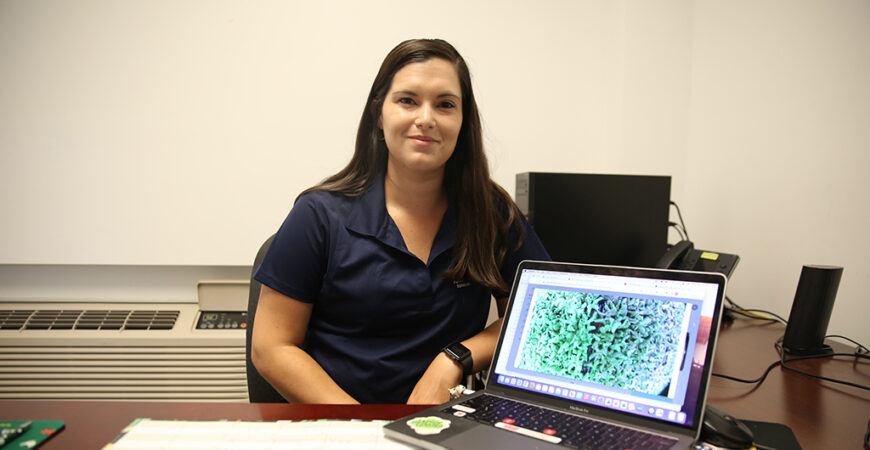

KENANSVILLE — Growing up on a farm instilled a natural born passion for agriculture in Katlyn R. Foy, agricultural instructor, and smart farm manager at James Sprunt Community College.

The Beulaville native received her bachelor’s in agricultural education from NC State University, graduating with a minor in agronomy. She has a master’s in agriculture and extension education and in the fall, she plans to attend a doctoral program.

Foy moved back home after teaching agriculture education at NC State for two years and was then offered a job teaching at JSCC and the rest is history.

Foy taught the first hydroponics class at the smart farm, which is housed at West Park Industrial Park in Warsaw, last June. This was the first of a future series that will be part of a certificate program. Students learned about system operations, seeding, transplanting, harvesting, crop trials, yield analysis, sensor calibration, and mixing plant nutrients, among other topics.

According to Foy, the first class was an overview of everything an operator would need to know to run a hydroponic system. The next classes will break down more specifically for each category. “The second class will be all about seeding, what goes into that. The next one will be cultivating — what goes into that upkeep-wise, maintenance-wise, data collection, things like that. Then it will be harvest and we will go into the last class, which is all about marketing and profitability. So, if you want a hydroponics farm of your own, you know what you need to do to make that happen.”

According to Foy, the smart farm first harvest produced around 200 pounds of lettuce, approximately 20 pounds went to Sparty’s Cafe, 60 pounds to Charity Rebuild, 20 pounds to DNA Youth Community Center, 20 pounds were used at the NC Blueberry Festival, and 50 pounds was distributed among JSCC’s staff and students. Foy also shared that Sparty’s Cafe will be using lettuce from the smart farm to make lettuce wraps at the ribbon cutting ceremony, planned for July 29.

“We’re going to try to work with the family consumer science teachers at all the high schools to provide them with stuff for their cooking classes … that way they don’t have to outsource the produce. Another thing that we’re going to try to do is bus in bags in the school systems, kind of like a food pantry in a way, so the students can take bags home on the weekends,” said Foy, adding that any produce leftover will be distributed among the food pantries, churches and other charity organizations in the area.

“Our biggest goal is to keep it local, to try to help, give back to the community and benefit Duplin County,” said Foy.

Currently, Foy and her students are growing collards, mustard greens, cabbage, oakleaf lettuce, kale, Swiss chard, and nasturtium at the smart farm.

Foy told Duplin Journal that another of her main goals is to have zero waste.

“We’ve tried to incorporate the hydroponic smart farm into all the ag classes that we have on campus, even the animal side of things… we’re going to end up trying to make feed from the leftovers that we have out here,” said Foy. “There’s going to be no waste from it.”

Foy shared that the seedlings that are not big enough to make it into the cultivation wall, will be distributed around campus and be put to beneficial use in other classes like sustainable ag, soil and plant sciences. “Those seedlings will go to use for the students,” said Foy.

The cutting age technology of the hydroponic container enables students to grow organic produce with soluble nutrients in a climate-controlled environment. And can produce an equivalent land yield of 2 to 4 acres annually using an average of 5 gallons of water daily.

Foy has been documenting the plant’s growth with time lapse photos. “It was the craziest thing I’ve ever seen,” said Foy, explaining that from about day three to day six the seedlings had transformed into an actual plant.

She explained that most hydroponic systems, as opposed to the one they have, are flat floating bed systems where the plants sit in the beds and the water runs through.

“These are vertical. So this is vertical hydroponics farming, which is two things at the same time,” said Foy with excitement, adding that the long rows that go up and down, take less space.

“You can also fit more into it, which is kind of mind blowing. But it pretty much brings vertical gardening and hydroponics together, which is such a crazy concept.”

Foy shared that the smart farm also cuts down water waste adding that everything is recirculated.

“The tanks self-sustain and once the tanks fill, the nursery tanks will fill and then once the plants take up whatever it needs, it’ll flush back out into the tank and then also when they’re in the cultivation walls, the water literally just recirculates in the whole farm. So, there’s pretty much no waste.”

When they say smart farm, it is really a smart farm,” said Foy. “You can control it from anywhere that you have a Wi-Fi connection. I can see, at all times, what’s running in there. It will tell me if the lights are on, or a pump is running… I have constant access to it. So, if I am in a different state and I need to make a change, I can. I think that is the coolest thing.”

Built in a 320-square-foot freight container, the smart farm is the first of its kind in Duplin County and is the product of a partnership between the Tobacco Trust Fund Commission, Four County Electric Membership Corporation, North Carolina Electric Cooperatives, Duplin County and JSCC.

Twitter

Twitter Facebook

Facebook Instagram

Instagram